Quality

Quality Certificate

ISO 9001:2015

ISO 9001:2015

Awards

Award for Product Innovation 2019 from TATA group

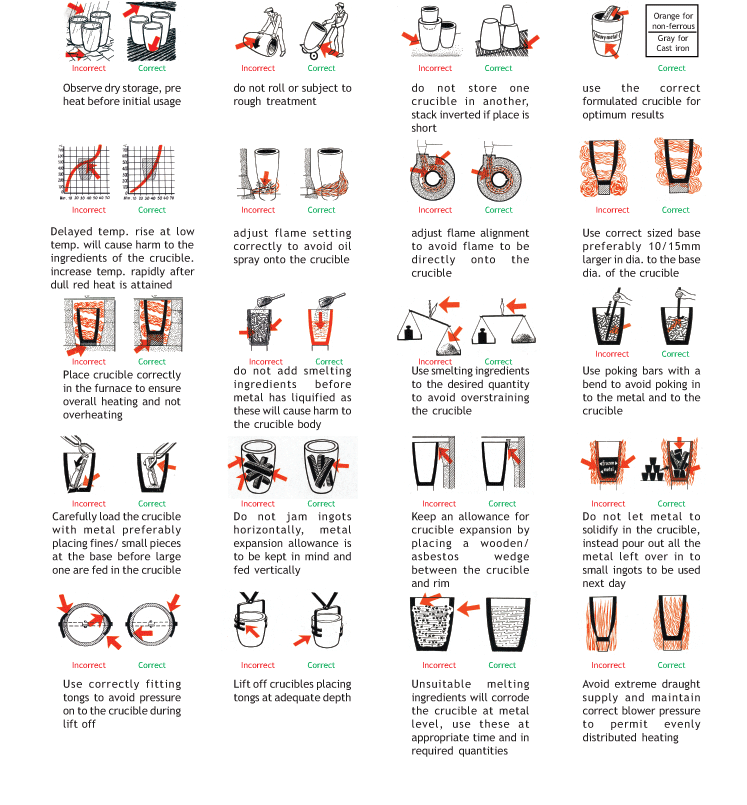

Care and Use

Properties

High resistance to thermal shock

Crucibles in use are subjected to stress by rapid temperature changes, and in extreme conditions cause premature failures.

Our careful selection of product ingredients ensures an outstanding resistance to thermal shock by rapid heat transfer.

High erosion resistance

Metals when melted are abrasive and cause erosion to the crucible.

High silicon carbide content and a high strength with hardness counters resistance to erosion.

High resistance to chemical attack/slag resistance

Alkaline fluxes for light alloys and oxidation/ reducing fluxes used for copper alloys form corrosive slags which corrode the crucibles.

The careful ingredients selection impart a quality that counters corrosive attack to the crucible in use and achieve a high life.

High oxidation resistance and high conductivity

Normally exterior glazes are provided to crucibles but these are not fully protective to the crucibles in use.

Triple glaze mechanism provided in the body imparts protection throughout the use in every melt and ensures a constant melting speed.

High oxidation resistance and high conductivity

Normally exterior glazes are provided to crucibles but these are not fully protective to the crucibles in use.

Triple glaze mechanism provided in the body imparts protection throughout the use in every melt and ensures a constant melting speed.

Lower metal loss

With each melt, metal oxidises proportionally to the time taken per each melt.

Rapid melting looks after the lowering of the metal oxidation.

Cost Effective / High Life

Finally the cost of each melt is of importance.

With a good product management, a rapid melt and a high life, a low cost per melt is achieved.